Leaderboard

Popular Content

Showing content with the highest reputation on 02/20/2018 in all areas

-

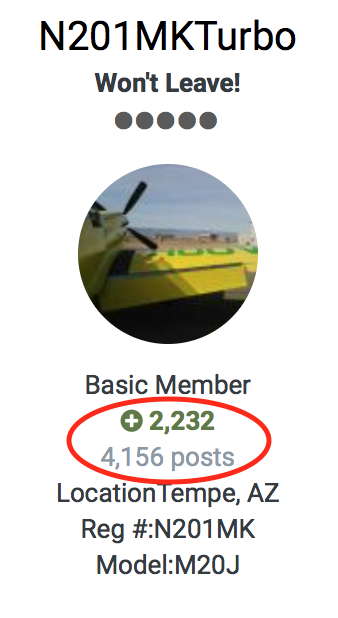

An internet forum like this one is really one long extended conversation. During the course of this conversation, sometimes some of us get a bit worked up and fly off the handle. Also there are those who come and go in the conversation and those who stay around. Those who have stayed around and become part of the long and ongoing conversation build trust. Not because we take everything they say as the gospel truth, but because there is a certain tenure that goes with becoming a trusted member of the community. Under each avatar is a +number. That number is basically a ranking of trust and standing within the community. It would be wise to take that into consideration before starting a flame war. Internet posts are very easy to misunderstand. It's very difficult to catch subtle and context in written posts. This is all the more reason for caution and civility as to not look foolish by misunderstanding intent, meaning, or even the words themselves. Those who choose to disregard, are typically first ignored, then blocked, and then they fade away to bother other people in other places. Think, read, edit, and consider before posting to avoid embarrassment.9 points

-

Just out for a quick flight to give @"Chocks" a ride to pick up another plane. I get back home and JD from SWTA is waiting with the golf cart to help put her away in my hangar. I couldn't help but think how lucky I am to own such a wonderful airplane.7 points

-

Thanks for all your support guys. I was just trying to share some of my experience's with ice on Mooney's. I'm sorry some thought that I was encouraging people to fly in icing conditions, I'm not. But if you fly IFR in your Mooney you will at some point get ice on your plane and have to deal with it in flight. Sometimes it has to be an emergency response and some times it doesn't. It would be good to talk about this so the new IFR pilots have a better idea what to do.7 points

-

I find most of your posts quite useful whether we agree or not. I appreciate you relaying hard won experiences. I did not sense that you were advocating conducting Non FIKI aircraft operations in ice as a matter of SOP. I think that fear is an overrated motivator. While it heightens senses, releases adrenalin and increases heart rate, it does little to improve one’s ability to handle the challenges of managing a stressful situation in the cockpit. Fear that has degraded to panic can reduce a formerly well-functioning pilot to an indecisive mass that acts as if they’ve had no training. I have always disliked the “178 Seconds to live” CASA campaign and all of it’s offshoots. Telling VFR pilots that if they enter IMC they will depart controlled flight in less than three minutes on average might motivate them to steer clear of IMC, but it’s not helpful if it happens to one inadvertently and may lead to panic (and the performance degradation that comes with it) when calm assessment and decisive action would save the day. Ice in a non-fiki bird is not to be taken lightly, but the OP ended up encountering ice in the descent when there was no forecast of icing. Having just passed some large rocks prior to descent, it seems his only real option was to continue the descent and approach. In that situation, I would much prefer to know that the bird I’m flying will carry a reasonable load of ice before becoming a stone than wondering if I’m on the edge of a stall with a light layer of rime. I would not be comfortable with ice out to stall strips and your post makes me no more likely to fly in icing conditions. However, knowing the airframe will carry ice would likely provide some measure of comfort (an antidote to panic) in an inadvertent icing situation because it’s good to know the airplanes abilities exceed the comfort level of the pilot by a large margin. When that situation reverses or is an unknown, bad things can happen quickly.5 points

-

This thread on icing has been quite passionate. A story about flying in icing conditions and what happened. It was great that it worked out for you and you made it on the ground safely. I am sure a lot of us have stories like it, I do. I am also new to the Mooney forum. I started out a small single engine Pilot and have worked my way up the ladder to ATP flying all Boeing airplanes. I have been flying since I was 17 and now have 45 years in aviation. I don’t claim to know it all, in fact this website is a great example of crew resource management. But I do take issue with low post numbers for credibility. There is no argument that flying in icing with no anti ice or deice is a dangerous situation. I recall a few years ago, on the east coast, a single engine turboprop stalled in icing conditions and could not recover from over 10,000 feet. If you are an instrument rated pilot you will eventually encounter ice. Early detection is critical. At night even in the Boeing I have my flashlight out and check the windshield wipers all the time when in icing conditions exist. Anytime icing conditions exist engine anti-ice is on. Getting back to the original story, every icing encounter is different and as you fly through the precipitation the density varies along with temperature. One ice encounter you may make it through and say I won’t do that again or you may become another accident we will hear about with a tragic outcome. Be careful and always have a plan B and C for “just in case”when in the clouds, just as you would for mechanical failure. Fly safe, Kevin5 points

-

That's a very good practice to do and doesn't take a lot of time for something so important. Unfortunately, the accident report left important questions unanswered about whether it was the high pressure line or the low pressure line that had a loose fitting: "An oxygen tank was located aft of the aft bulkhead. An elbow fitting that was connected to the oxygen regulator assembly, which connected an oxygen line to the tank, was found loose. The fitting could be moved in both directions by hand without resistance." I would guess it was the low pressure line with the loose fitting, only because since it had been 2 years since servicing the tank and regulator per the report. A high pressure line leak will leak out while the system is off thus allowing ample time for the pilot to notice loosing all the air while sitting on the ground and not just going through the air faster than normal. But a low pressure leak will only leak out air when the regulator valve is opened in the cockpit (or fails to shut off). This is obviously the more insidious failure since its only leaking in the delivery line while the valve is open and the pilot is less likely to notice his O2 is draining at faster rate than normal. However, such a leak , which is limited by the regulator, is still going to take hours to drain the tank. Plus as pilots we still have two devices to protect us, the O2 tank pressure meter which shows us the remaining tank capacity as well as an O2 Pulse oximeter. One was found in the cockpit in this accident. Per the accident report, the pilot took off about 12:00, read back an altitude assignment clearance to FL250 at 12:16 and then was non-responsive to ATC query 23 min later at 12:39. Its really hard to imagine a circumstance by which the pilot could have just taken off with a near full tank of O2 and seen it drain in half an hour even if it did just happen to have the high pressure line become loose at take off - which is highly unlikely and still too fast to drain a tank. More likely the tank, which had been serviced with O2 3 months prior at annual was already getting low and the pilot figured he had a enough for the 2-3 hr flight yet didn't notice the tank meter draining while in his climb to FL250. I wonder if he even got a chance to use his pulse oximeter or look at the flow meter attached to his mask before he succumbed to hypoxia. Very sad. But it underlines the diligence pilots flying alone in the flight level must exercise in monitoring their O2 supply, O2 flow level, saturation level and be alert for any symptoms. In my personal history it has always been the awareness of the symptoms of O2 saturation dropping below the 90's that got me to look at my flow meter and realize something was wrong and fix it. The pulse oximeter has enabled me to set my flow to achieve a desired % saturation level but has never saved me to so speak. The flow meter does that easily and if that can't be fixed, the backup emergency O2 cartridges are in the back pocket. Which luckily I have never had to use.4 points

-

Does this mean you love me or just my girls? The internet can be a great source of truth or provides the greatest lies. It does come down to the source of the information and the history of the poster (imposter). As well, written word often loses a lot in translation. There is no body language or other signs of intent to read. At least that is the explanation I am giving myself when I read Peter Garmin’s posts. Surely he jests... Sent from my iPad using Tapatalk Pro4 points

-

It’s funny I’ve been ridiculed for so many posts. I’ve only gotten icing a few times in many hours but twice it stands out. Once I was flying a 402C from North Platte, NE to Denver. I was droning along in the clouds for about a half hour when I heard a static sound like flying in rain. I looked outside wirh a flashlight and alarmingly, I picked up 3” of ice in about 3-5 minutes. I was close to Denver and getting vectored for the approach so I stayed with it. As I started down the approach it was icing up further and the boots weren’t helping at all. The heated windshield on HI was icing over to. Gear came down and prettt soon it took all 650 HP from those twin TSIO-520VB’s just to maintain glideslope wirh flaps up and gear down. Thankfully I broke out at 200’ and landed. When I eased the power off at 10’ the airplane stalled at 100KT. Later I was a Ca in a Beech 1900D. A legendary plane for climb and ice. Same situation, vectored for an approach in Kingmam, AZ the ice appeared in the tips of the clouds. Only this time it was mixed and rime ice and it was 2-3” a minute. Now a 2700HP airplane should handle it just fine and it is, but it was losing 30kt in the 30sec it took to manually inflate all the boots. Since then I don’t get anywhere near clouds near 32 degrees in a non deiced airplane.4 points

-

4 points

-

Wow. I just wanted to share some stories of a personal experience for knowledge of the common good. Play nice and keep the ad hominem to a minimum. I'd hope people aren't taking flying advice from a bunch of anonymous people on the internet. There is value to both knowing the rules and explaining what happens when they are broken. Fly safe.4 points

-

I just noticed that number of post counter - and I thought dang I’m here too much but wow some of you guys triple me! Here’s to old timers!3 points

-

3 points

-

JT, I'm busy drawing up and making a couple of M20J/K panels, here's where I am at so far. This is a result of surfing every available panel project I could find on Mooneyspace and the web. Personally I like the 3/4 and 1/4 panel, because it will allow the retention of the original circuit breaker panel, or replacing the circuit breaker panel first to hold all the wires in place before you deal with the main panel. The late model Mooneys have the same 3/4 and 1/4 layout. But once drawn, there is nothing stopping me from adding a line and cutting in different places. I'm picking up a used panel tomorrow (thanks Scott), then will do one more revision to the panel before cutting. I've got a good library of instrument shapes, but need to refine the perimeter and mounting holes. The goal is to be able to simply screw the new panel in place with a new set of instruments. Feel free to email me: supercub180@gmail.com Don3 points

-

FYI .................... Greenville Air Avionics is advertising an Aspen PFD Pro 1000 installed for $9,100. Just sayin'3 points

-

Competition is good. Early GTN650/750 owners have benefited tremendously from the IFD440/540. New features have come out on the GTN since 2016 to keep up with what Avidyne had - bluetooth flight plan transfer, pinch to zoom to name a couple. Advanced features that the IFD's don't have yet have come out on the GTN to add value (telligence, visual approaches). It's been good for consumers when these companies try to stay ahead of one another. I can't wait to see what's next.3 points

-

Perhaps. I've seen some shoddy work over the years, but most IAs that would undertake an engine overhaul are pretty serious folks. I would also submit that an O360 A1D is about as simple as a multi cylinder engine gets. The parts get sent out, tagged and reassembled to spec. There are no surprises, no confined spaces to deal with, no "airframe specific" quirks to misunderstand. Just a simple, air-cooled, 4 cyl with easy access to everything when on the stand. I'd be far more skeptical of something like a GTSIO 520 that was field overhauled, but I've also seen those rebuilt in the field to a high standard.2 points

-

It all comes down to how well the present overhaul is documented. A very detailed listing of what was done and what parts were replaced/reworked goes a long way to peace of mind. If all the new log says is "Engine Overhauled this date" I personally wouldn't touch it no matter who did it. When I did mine, I have 2 pages of detail on every item that went into the engine.2 points

-

That's a great price! Unfortunately I don't think that includes the EA100 which allows you to get rid of the KI-256. But for another $2795 (list) you can get that. That would make it 11,895 compared to Peter's quote of 11,600 for the G5 and KI-300. How about we all chip in $10-$20 each to pay the $295 difference so Peter can get the Aspen he's always secretly wanted?2 points

-

Wow! That many? How time flies. I need to get a life instead of hanging out with the rest of you neanderthals. There is plenty of time to do that in the nursing home.2 points

-

"Missing" engine logs are not a big deal and is not uncommon for large shops. It is true that only the factory can '0' time an engine as brand new, but that isn't an important number. Time since overhaul is the only number that matters since there aren't any life-limited parts on one of our engines. The parts are either good, or they're not. An engine overhaul should have airworthiness tags for all components with the exception of standard hardware. This is an important consideration regarding parts: what is the engine, really, other than a collection of airworthy parts assembled together? Every single part of your 50 year old engine could have been replaced over the years, to include the crankcase that has the serial number. Does it really matter that the crankshaft was reground 30 years ago if it was replaced with a new one 10 years ago? ADs on our engines must all have been complied with, but again, this will be shown in the engine logbook. Many of these ADs are doubly important because they become effective when the case is opened for any reason. As an example for why all-original logs for an engine aren't very important is if you were to exchange your engine for a freshly overhauled one from a large shop. Odds are you will get a new logbook that documents the overhaul in extensive detail but you will have absolutely no data for its previous life. Obviously, this would not be the case if you had your personal engine overhauled. The shop overhauling your engine wouldn't even care to see your previous logbooks, they would just give you a brand new one.2 points

-

2 points

-

I've read through the posts and I think some of the information being provided to you is old information, other information is slanted. The message from Dale that you quoted is not unexpected. All of these manufacturers are competing for the same piece of real estate that Garmin is. Avidyne, Aspen, BK and L-3 are working together at different levels and support each others products. Garmin has taken a different track. They support their stuff first and then, being the shrewd business people they are, address the rest of the market to make sure there are no table scraps. Case in point. The GTX-345 when first introduced worked with their G500 (with I believe a firmware update on the G500). It didn't work on the Aspen. I'm sure not to lose sales to other competitors for the Aspen business, Garmin eventually allowed integration with the Aspen system. A GTX-345 will display traffic and weather on the Aspens. My advice as someone who has done a fair amount of avionics upgrades is to develop a must have list of features and compatibilities you need. Garmin is clearly an integrated solution, but if you are dead set on using FlyQ, good luck with making that work. Even ForeFlight (a Garmin supported app) is not a given with the Garmin suite of avionics . In my particular case, flying a single engine, one electrical system plane, I wanted to have electronic redundancy. The G500 does not have a battery backup. It also could not do a PFD to MFD reversion (I think the new touch screen does though). Pick what is important to you and look for the feature sets in the available technologies. I wanted active traffic without spending a lot more for it. With the amount of glass I have in the plane, the iPad app plays a secondary role. My plane is equipped with an Aspen 2000. It communicates seamlessly with the L-3 9000+. It communicates seamlessly with the Garmin GTN 650. The 9000+ sends traffic only to the GTN but I heard weather is now available. Not an urgent need for me since the Aspens both show weather as does the L-3 on it's own display. The 9000+ talks with a host of third party iPad apps but not Garmin Pilot. I like Garmin Pilot and if I did not have the Aspens or the L-3's displays I would be looking at a different solution. Garmin Pilot has the concierge function which works with the FlightStream 510 (only app that does). And it is my understanding the Avidyne integrators are all integrated with the non-Garmin hardware. So, how do I use all this stuff? The iPad with Garmin Pilot is relegated to the database update tool and manages the flight plans that I send over to the GTN or receive back from it. The app is used also for pulling up the approach plates. No traffic, no weather. The Aspens are used for displaying the flight plans, navigation and for traffic and weather. On the L-3 9000+, if I am enroute, will have the traffic set to the 2 mile range on the left side and the right side will be used for weather, METARs, etc. The GTN 650? for selecting Com/Nav freqs, VNAV calculations, selecting procedures, etc. I also have FltPln Go loaded on my iPad and is the backup to the backup for weather and traffic since it is an app that can be fed from the L-3 9000+ and it is FREE. Stay on the quest....2 points

-

My front cowling was definitely not that smooth going into the shop. They repaired some delamination of the lower cowl and installed a new heat reflective blanket. They also did some fiberglass repairs to the upper cowl to smooth the surface. I had ding on the leading edge of the horizontal stabilizer which they also repaired. They believe this surface prep is critical in the processs to obtain the best overall finish. It’s almost a restoration rather than just a paint job.2 points

-

Not the same set of facts, but I won the Jepp subscription fo a year at the Mooney Summit, nearing my renewal date I received an invoice. A couple calls to to customer service straightened out the situation. Like most big companies the computer systems are not always on the same page. Try to get a matter fixed with the IRS.2 points

-

2 points

-

Skates, a few of us formators are meeting at KCMA Saturday 24 Feb for practice. While we aren’t holding a clinic, you’re welcome to come out and watch a brief/debrief and ride in someone’s right seat to see how it all comes together. StinkBug can’t make it that day but we are trying to set our next meet on a day he can make it. If you’re planning to fly to OSH with the Caravan, register at mooneycaravan.com and we will get you form-qualified for that. If you’re just wanting to try it, come take a ride with us. If the bug bites, you can come prepared to a clinic and try it yourself to see if it sticks. Warning: It’s very addictive. Sent from my iPhone using Tapatalk2 points

-

Great! No worries! If you have any questions or anything we can help you with, just let me know. We are all in this together and if we can give advice or help, just let me know.2 points

-

2 points

-

2 points

-

Riley and I went flying yesterday with the new induction system and the louvered bottom panel. The induction system is great! There is very little restriction now. I am seeing only 0.6 - 0.7 inHg difference between ambient pressure and WOT on take-off. Previous, I was seeing a delta around 1.2 inHg on take-off. I think that is about as perfect as it gets for a NA airplane. At altitude, the MP seems to be ~ 0.5 inHg different (lower) than my previous flights with RamAir open. The conclusion is, with the new intake, the RamAir would create a negligible difference; at best, maybe 0.5 inHg difference. That makes it unnecessary in my book. With the removal of the RamAir, came a very clean installation under the hood (I will have pictures later) and it cleaned up the front nicely (see attached pic). A side-effect of the intake is that my engine idles very smoothly! Before, it would run like a big-block Chevy at idle when warm. That problem is long gone! The fact that the induction boot was ripped probably had something to do with that. Regardless, the engine loves the smooth intake air. As those that have followed this thread for a while know, we are seeing increased CHT's with the removal of the third cowl flap. We really wanted to keep it gone because it makes such a clean installation. Unfortunately, the latest test data indicates a simple louvered panel is not going to cut it. David will be reinstalling the third cowl flap shortly and we will have results after that. So the tweeking (not twerking) continues......2 points

-

2 points

-

2 points

-

I'm jealous. Your plane looks so clean. I know mine has a few dings, but yours looks flawless.2 points

-

2 points

-

I suspect the vibration was from prop ice. No electric prop deice? Picking up a trace in descent is the least hazardous way to experience it; especially if you are able to descend to below freezing. You may have picked up more on the elevators though. But it’s harder to judge the loss of performance in a descent compared to level flight when you will notice a speed drop as accumulation increases. One isn’t going to get cited for flying where there might be a pirep for icing or even forecasted icing conditions. It’s all about whether your plan had reasonable outs or plan B’s and you exercised them to get out of icing conditions. That’s perhaps overly simplistic but the FAA really leaves it up your judgement and planning. Sent from my iPhone using Tapatalk2 points

-

2 points

-

2 points

-

1 point

-

My Factory engine came with the logbook and entry saying that it was zero since major, 2425 hours since new, but no logs previous.1 point

-

1 point

-

Perhaps one of the more important tips I learned while in A&P school and just as valuable to pilots: "Never inspect the prop and spinner with the engine running, its much harder to see that way!"1 point

-

Yikes, the weather's been pretty awful and supposed to stay that way this weekend. There might be a little break early Friday, and I'll help out if the weather gods smile, but it's likely it will be below my comfort level for a round trip. Let me know how things go and I'll keep checking the weather. Hopefully, the weather will be better when the annual is done, and I can definitely give you a lift then. I'm based out of KCVO now, so PM me1 point

-

I might have missed the middle ground of putting it on a Semi Truck? Of course the price has to be right!1 point

-

I believe it’s intended to simply illuminate to assist in viewing the fuel selector switch setting (on the floor under the pilot’s feet).1 point

-

But you're still here with a likability/trust score of +2812 and a very well respected member of this community. And while we never agree with anyone 100%, your insight and opinion is obviously valuable and very much appreciated around here.1 point

-

Here's how to do it: 606-00182-015.pdf It will also do traffic if you read through the instructions.1 point

-

Some important details for those still reading... First, while all the pros thought it fine to put one thin washer on the head side of the bolt, I'd caution against anything more than that. The grip of the bolt (i.e. the length of the non-threaded portion of the shaft) is clearly supposed to extend all the way through both forks of the forked retract truss. The 0.750" grip of an AN26-17 bolt does just that. A single AN960-616L washer draws the bolt head back 0.032", leaving 0.718" of grip, which I was comfortable with based on a visual look - I could still just barely see the edge of the grip shoulder at the surface of the retract link indention. I also tried a standard AN960-616 washer, which has a thickness of 0.063". That results in a grip distance of 0.687". I was uncomfortable with this visually - the thicker washer drew the bolt back far enough that I could no longer see the grip shoulder on the nut side. Based on this observation, swapping the AN26-17 bolt for an AN26-16 would not have been a good solution either, as the grip on the -16 bolt is only 0.688". Second, I double-checked with DMax on this (actually got to talk to Don himself, which was an honor). Don was OK with the washer solution, but said he would probably have just installed a thinner shim behind the "baby shoe" bracket. He also said some airplanes have no shim at all there, just like in my "experiment" video above. In fact, I walked out and looked at another Mooney on the ramp, and it was entirely shim-free - the baby shoe bracket was installed directly against the wing spar strap. I'm still not sure this is a great idea, but I'm really in no position to question Don's expertise. The main reason I didn't go that route is I didn't want to order or machine a thinner shim, and going with no shim at all seemed like it would place too much side load on the bearings during operation. Finally, one mechanic asked why I didn't just install the bolt in the other direction, despite what the parts manual says. We looked into it as a thought experiment, and there are a couple of reasons not to do this. The more important one is there are clearance issues on the other side of the retract truss too, and the consequences of interference on that side would be more severe. The less important one is we came to the conclusion you might be able to remove this bolt and nut without removing the entire landing gear leg, with the parts installed as shown. If you flip the bolt around, it would be absolutely impossible to do so. I still have to re-install the rods and swing arms, then check the gear rigging, so too early to declare victory yet. But good progress today.1 point

-

Here's my website for solar. I have a lot of information on there as well as links to a few other good solar DIY sites. For specifics on building hot water solar collectors, look under the menu tab "Solar Projects". I have a hot air collector on my hangar too. Very cost effective project. https://www.aluminum-solar-absorbers.com/ My friend Gary has probably the best Solar DIY site in the world. He has so much information it's almost overwhelming. http://www.builditsolar.com/index.htm Tom1 point

-

I’ve been running LOP a lot, especially in the hot summers, I find it easier to keep the engine cool vs rop. i sit around 1590 lop and 32-34” and 2450-2500 rpm. Not or flying over 12500 right now, but those numbers work well for 9500 to 125001 point

-

I know its only the masking tape, but that shade of yellow looks stunning with the silver. Reminds me of the carbon cub.1 point