Leaderboard

Popular Content

Showing content with the highest reputation on 12/08/2022 in all areas

-

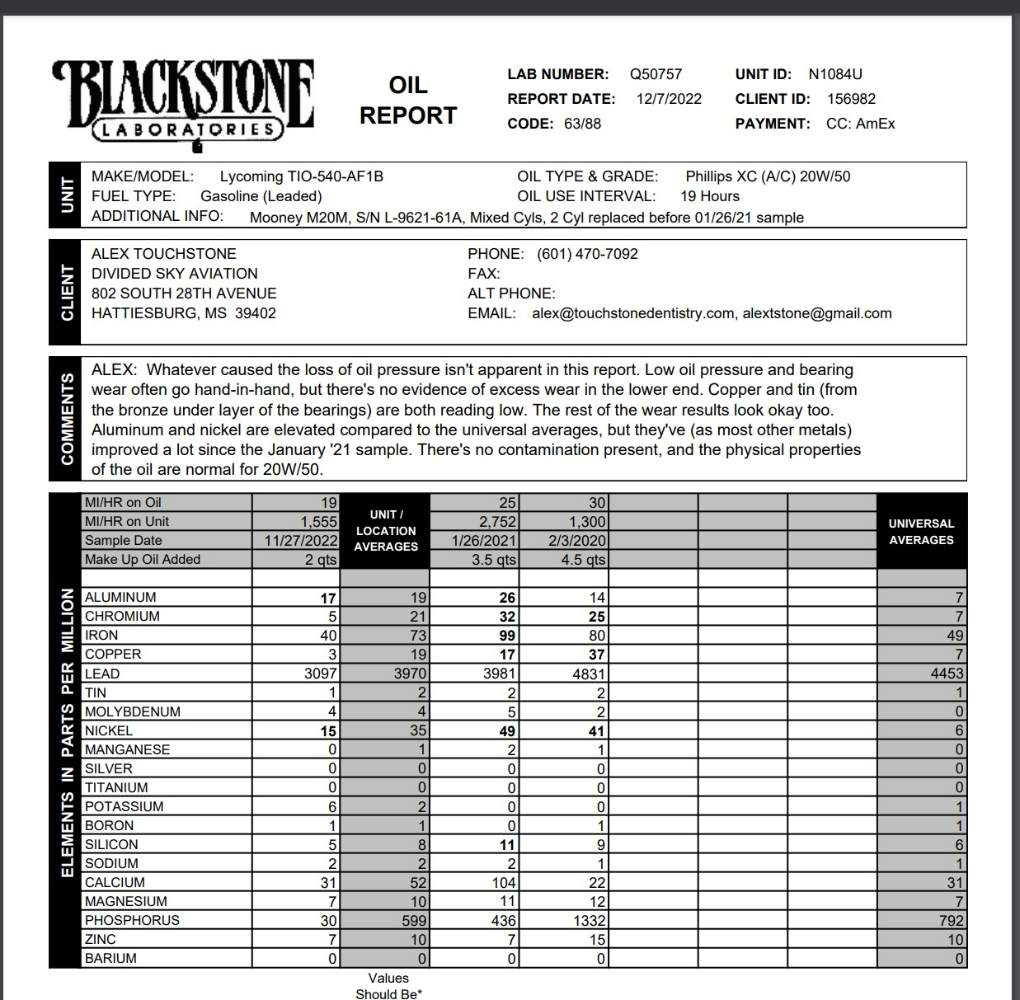

I have an update to share that I think will be of interest. First, have a look at the photo below. It is a photo of the filter PRIOR TO the event. As you can see, the filter is seated fully. If the mechanic did pinch the quad seal causing it to become displaced upon tightening, it is my assertion that this is due to a poor design and the manufacturer should mitigate the problem. Unfortunately when I contacted Challenger and spoke with their CEO, she elected to have their attorney contact me and demand that I send the filter and seal to their chosen lab along with my aircraft to their chosen shop in their home state. No offer was made to offset any costs. I elected to ignore this demand for a period of time during which I could determine what my damage, if any, might be. I did the following: 1. Ground run the engine for 1 hr. Cut open and inspect filter and remove oil screen. The deposits found in the screen were all carbon. There were a few particles of non-ferrous metal in the filter. 2. Fly the aircraft in VFR conditions for 5 hrs. Cut open another oil filter and remove the oil screen again. This time, no particles were found in either. 3. Fly the aircraft for an additional 13 hrs for a total of 19 hrs since the oil addition after the event. Drain the oil, cut open a third oil filter and send an oil sample to Blackstone for analysis. Here is the result: As you can see, it is a near perfect report and the trends are all in a positive direction. Next, I borescoped each cylinder. No issues to report. Compression checks were attained. all cylinders were 76-78 / 80. At this point, I consider this issue behind me although I will additional oil samples for analysis. BTW: As for Challenger, I will contact them to update them although I am very disappointed in their stance so far, I will also file an SDR with the FAA now that I have more data to report. Lycoming will not analyze any samples that are from engines that are not currently in warranty so that was a non-starter. For those of you who recommended immediate removal and teardown of the engine, I hope my decision to go another route does not seem reckless. I feel that I made the correct decision given my own personal risk tolerance and the data that was generated along the way. Thank you all for your input.12 points

-

THIS^^^. If the pilot following goes around it is because that pilot (or the controller) screwed up and got the spacing wrong. You own the final approach and the runway until you exit it.9 points

-

When you are up to bat and in the batter's box you swing away until you're out or get a hit. If the batter behind you can't wait, that's his problem.9 points

-

I had a young USAF instructor who worked for me in Texas. Came into my office pretty mad and told me he grounded himself for the rest of the day (which was what I usually did when someone did something dumb, but I hadn’t ever had a “self grounding” lieutenant). I asked what happened. He said he was flying solo for practice since his student was on his formation checkride. The IP ended up in front of the student in the pattern, but he was scared the student was close behind him (we could land alternate sides of the runway as long as the preceding plane was 3000’ down) and he would bust his checkride if he was too close or messed up a go around. So the IP decided to help him by making the first turnoff. Jumped on the brakes and Blew both tires and shutdown the runway. Student went around and passed his checkride. IP got to help maintenance change two tires. Never worry about the guy behind. Don’t stop on the runway and do your checklist (unless you can’t see the exit properly), but take all the time you need to exit safely. If/when tower tells you to get off next taxiway, remember that’s a request, not an order. Unable works.5 points

-

the way to get the guy behind you to slow down is to use the callsign "Citabria 8CS"4 points

-

I flew to Philadelphia the last week of November. This was from fairly early in the flight and I thought this 4-minute video would be interesting on its own. Kudos to the Washington Center controller for patience and taking the time to spell things out. Besides, I was flying a Mooney.3 points

-

3 points

-

Sounds like the planes behind you needed to extend their downwind another 15 seconds or so,. They will learn eventually.3 points

-

You should never feel hurried. Do what you feel most comfortable with. There are a lot of folks out there (including the FAA: Airplane Flying Handbook (FAA-H-8083-3B, Chapter 8, Page 8-3) that preach stabilized approaches (fully configured with no changes) whenever you are on final and inside the FAF. However, once you become comfortable in your aircraft, you might venture into slightly higher approach speeds, using "approach" flaps, and then choose to lower your flaps to the full flap setting only when you are landing assured on short final. Whatever methodology you take, you should never feel hurried. - that's step #1 of most mistakes.3 points

-

But they do have it. https://www.faa.gov/documentLibrary/media/Order/Order_7110.125_Controller_Pilot_Data_Link_Communications_(CPDLC)_in_the_ERAM_Environment.pdf2 points

-

I'm sort of impressed and astonished that we still do reroutes and also initial clearances by voice transmissions on an open party line. That's so 1952 technology. Read back is correct. Not only does it take too much time, bandwidth and its annoying, but it does allow for more human errors and conflicts to creep in. Surely they can figure out a system where ATC can simply send us a text of some kind that if we approve then we hit a button and it inputs to our gps for final approval and then nav. If nothing else... here's an idea using current infrastructure: We already have an ADSB system up and running. I receive weather and traffic. What if ATC had the ability to push texts into the ADSB system in a new special category of information that was sort of like a party line, that while all the airplanes could see the pool of information there would be texts in there in just a big list that would have a syntax something like: ***N314EB reroute: ART, Letus, MSS, direct. Then ATC could say N314EB new reroute in ADSB text pool, confirm upon receipt. Then I would have the option to confirm once I receive it and acknowledge reroute, or if for chance I can't find it or I am not properly equipped I could still request the reroute to be read to me by voice in open channel.2 points

-

I just watched a documentary on the WWII B-24. They rolled out more than one per hour from the factory2 points

-

Maybe the rules at an FTU are different, but if we had to recover a jet off the runway with blown tires, that would involve the purchasing of some beer…2 points

-

To echo what @Ragsf15e posted, you own the runway as long as you're on it. Certainly you should be reasonable (don't pitch a tent and camp) but don't rush and make a critical error--gear retraction, turn too fast and collapse the gear (generic example not necessarily Mooney specific), etc. The other thing is you can't control what you can't control. At the towered airport many times controllers can apply reduced runway separation or category separation for a full stop landing behind a full stop or touch and go. However, there would be a different clear of runway standard if the succeeding aircraft were a touch and go versus a full stop. I'd always found that many times the go around was a result of the arriving aircraft not making sufficient adjustment to their pattern to account for the preceding aircrafts type of landing even after the pilot was advised. Finally at uncontrolled airport many people will apply a clear of runway standard when it's not needed/required by the FARs. That's their choice or comfort level that determined if they were to go around. Certainly at your first approach the succeeding aircraft was aware of your arrival and hopefully you announced your type of landing (i,e, full stop) for them to base their spacing. Again, you have to fly your aircraft and operate safely. The rest is on the other pilots to operate their aircraft safely. Control what you can control, work together to ensure efficient, safe runway and airspace use **Incidentally, I prefer 105 MIAS/90KIAS finals until the MDA or DH--that's a technique. The other most common technique is your approach--fully configured before the FAF. Do what you're most comfortable with and keep flying2 points

-

2 points

-

I keep the mag and door key on the same key ring. Key stays in baggage door lock until closed and locked. Can’t start up if the mag key is still dangling on the open baggage door2 points

-

The 67 by all accounts is the most awesome Mooney. Often folks with Acclaims will say otherwise, they would be wrong.2 points

-

1 point

-

1 point

-

And cpdlc was supposed to be mandated 2018 but as typical was pushed back then covid happened. It is still only working at a hand full of ATC centers (jackson center was not participating when we went Bos to Mia) and airlines still have to convert most of their planes with the new equipment. Only new aircraft are coming with cpdlc equipped. At least when all the airlines are forced to have it like RVSM was done then the frequencies will be more open for GA aircraft to talk on. But centers need to get trained up was well before that happens. On the other extreme Albuquerque center is testing out ads-c and assigning pilots to maintain aircraft spacing based on the aircraft in front of you sort of like adaptive cruise control on cars these days when driving on the highway. We were playing around with the equipment as it allows you to tag another tcas target and it gives you their call sign altitude and how much their speed is reporting currently as well as how much faster or slower you are going compared to the target. Haven’t flown through Albuquerque center yet with one of the new aircraft so haven’t been assigned a spacing yet.1 point

-

1 point

-

Yep. I could probably find some of those without looking too hard. It was the phrase "scrutinizing EVERY single application apparently creating a huge slowdown in processing." that made me imagine fraudulent applications.1 point

-

I’d bet lunch that I could repair the boot with A1/2 fuel tank sealer, just paint it on with an acid brush. It’s much tougher and much more adhesive than silicone. You probably could do it with B2 just think the A being thinner will brush on better and the 1/2 of course cures in 1/4 the time, may need two coats1 point

-

I did that years ago. Bought several for a rather unique project. Had to dispose of a few when we were done.1 point

-

Last year at F70 (another busy uncontrolled SOCAL training airport), I was getting jammed from behind on downwind by another aircraft. I announced that I was extending my downwind for spacing. Someone spoke up and said, great we won't be able to see you turning base. Yeah, I've felt rushed for years in SOCAL and many of my flying friends feel the same way. Some avoid F70 now. Appreciate everyone's feedback. I'm slowing down unless the tower asks me to keep my speed up on those long straight ins.1 point

-

That's fricking hilarious! In fairness, it may be that there are enough Mooney drivers out there who bomb onto final at speed, so people may be expecting that. The first M20J I looked at the guy said his normal landing is over the numbers at 100 KIAS I probably wouldn't be making friends if I called 'on final at Cessna speed'1 point

-

My understanding is the new system they recently released only requires the crash sensor (and its battery) to be replaced every 10 years and that is supposed to be a few hundred dollars. I think I got that from an Aviation Consumer article but might be wrong there.1 point

-

Honestly, I think the entire Mooney community needs to stop with various versions of the papa bear approach: "you gotta carry some extra speed on final in a mooney because the stall characteristics..." and replace with momma bear: "you gotta be on speed for weight and gusts"1 point

-

1 point

-

1 point

-

Yea full reroutes just plain suck especially when you get the waypoints all loaded in only to have the next controller clear you direct or worse another reroute grrrrr. box gymnastics no bueno.1 point

-

1 point

-

The class of resins, polyester (also known as “boat resin”) refers to orthophthalic resin. This is a relatively cheap resin that has poor strength properties. If used on parts subject to vibration, they will fail. A next step up is isophthalic resins. Big improvement from orthos. The next step up would be vinyl ester resins. This is a hybrid of the polyester and epoxy chemistries. This would be, for me, a minimum level if i were making an aircraft part. all of these resins can be used identically in fabrication. Chopper gun, hand layup, or resin infusion. Then you have to consider the reinforcement. C glass? E glass? Kevlar? Carbon fiber? Chopped strand mat? Cloth? Axial designs? Combo? Lots of choices. Each has a place. If I were building an aircraft part, I would use epoxy (west systems) with a light e-glass chopped strand mat then carbon fiber. The minimum would be vinyl ester and e-glass. my opinion as a chemical engineer who spent 30 plus years in FRP before turning it over to the kids.1 point

-

I just replaced the non-inertial reel ones in my 252 with the Alpha Aviation inertial reel ones. I am a big fan of inertial reel shoulder harnesses except in two areas. Track/race cars and aerobatic aircraft. One unexpected benefit is that the shoulder harness pulls the seat belt off the middle of the seat and up the side a bit. Much easier getting in and situated. A couple of things: 1) If you don't have shoulder harnesses, INSTALL them. It does you no good to have the wonderful Mooney steel cage keep the cockpit integrity, but you have douncing your head off the panel and are unconscious or already dead. 2) If you haven't replaced your seatbelt/harness in a while, REPLACE it. In race cars, we replace the harness every 5 years. My 252 had the original 1986 harnesses still in it. How much of the original strength was left?1 point

-

1 point

-

1 point

-

“Fabrication efficiency was greatly improved: While 24 technicians on three shifts could produce 10 first-generation skin halves per week, six technicians working two shifts can produce 16 G2 skin halves per week, with fewer subassembly steps. I thought I was reading a middle-school math problem: Assuming a fuselage is composed of two skin halves, how many people would it take to make 6 fuselages in one 8 hour shift?1 point

-

I have an LED beacon now, but when my original coffee grinder died it had a flash type beacon that produced feedback as it charged/discharged. This was installed and eliminated the noise. It was installed back in the avionics bay near the beacon. https://www.aircraftspruce.com/catalog/elpages/lsStrobeNoiseEl.php?clickkey=357951 point

-

Score another point for Halos! The "speaker" is about wooden pencil diameter and well under an inch long. Only silicone goes into my ears. Another point--they are compatible with wide brimmed hats, which provide much more cooling shade on those blistering hot days than a ball cap.1 point

-

There is no way your approach speed is lower than the generic 172 etc, unless of course your flying bomber patterns and slowing way out on final I guess.1 point

-

It would be nice if there was an option to annunciate when the auto trim was operating.1 point

-

Why? its not a mandatory SB nor an AD. The runaway only occurs at engagement if it occurs and is stopped by the AP disengagement button. My installer straight up said to do nothing other then monitor the trim during engagement and wait for the software update.1 point

-

Similar to the yellow device above; I bought this and then attached a set of cheap cables. The booster cables are soldered into the end permanently. This way I don't have to worry about finding someone with cables. It is light/small and I keep it in my plane at all times. All in (this part and cables) was about $75. https://www.aircraftspruce.com/catalog/elpages/jumperplug.php?clickkey=51945 Alternative #2 is buying this same setup already made for you; cost is $180. My setup is exactly the same for $100 less... https://www.aircraftspruce.com/pages/el/jumpercablesplugs_cables/jumpercables.php1 point

-

One of the things I try to impress on new Mooney owners to help prevent this is to always lock the hatch if it's down and closed. leave it up and open if it is not locked . Learning this simple standard practice will prevent opening in flight and is easily done with new owners before they get into other habits1 point

-

also from TERPS 2-1-4. Sloping OCS: "d. In the case of a missed approach procedure, the climbing flight path starts at the height of the minimum descent altitude (MDA) or decision altitude (DA) minus height loss. "1 point

-

I'd recommend getting rid of that useless CO detector and getting one the could actually save your life.1 point

-

If you’re looking for an excuse to buy 90 degree power wrenches I say just buy them. On one side they will not be very helpful on this airplane. On the other, you will have 90degree power wrenches.1 point

-

The shop labor at my marina is 135/hour. The shop labor at my airport is 95/hour. Who would want to be an A&P?1 point

-

@hobbit64 My self made excel spreadsheet is crude but highly functional - I have one section for the pilot and one for the plane. I include part numbers last replaced, next due etc. It's attached here in case anyone wants to use as a template. I couldn't upload excel format but can PM if desired. Maintenance log.pdf1 point

-

1 point