Leaderboard

Popular Content

Showing content with the highest reputation on 04/29/2018 in all areas

-

Panel In! Trillian has an upgrade! A G500 TXi and an Aspen Pro Evolution PFD with backup battery. New behind the panel is a is a wx 500 remote stormscope. I looked closely at my backup options including original steam gauges, l3 ESI 500, and aspen pro backup. Chose the aspen backup as it has a two hour battery, synthetic vision, can track two Nav sources, has a dual HSI display which I like and has emergency gps ( it keeps your last gps course so that you can fly it, unlike the others if you actually lose all electrical power, you would lose all gps info). Have to especially thank @donkaye and @Marauder ( I watched your you tube video on your aspen) and all of you that helped on this thread with my decisions along the way, thanks! Still working out issues with the engine monitoring eis system, but the txi display is so incredibly clear, makes every other display including the gtn 750 look like a so so you tube video compared with the latest 4K ultra high def tv in your airplane, love it!6 points

-

Late last year I decided to redo my panel in my 1964 Mooney M20C. Although there are two fine places in NJ for Mooney’s I have to keep my plane near palm trees for the winter months. So my choice was to either fly back to Van Nuys or head back to Florida. Florida just seemed like an easier trip from NJ. I researched on mooneyspace about avionics shops in Florida and several people said positive things about Daytona Beach Aircraft Services. They just happened to be a Mooney Service Center and I needed my annual and some other stuff done as well. One stop shopping sounded great to me. I exchanged many emails with John their avionics guy and Jake the person who runs the shop. On a very short notice they said bring it down and although they can’t promise it could get in right away that I could keep it on the ramp out of the NJ cold. Within a week my plane was taken into the hangar and things started happening. I asked Jake for a very specific layout and he and his crew delivered 100% of what I wanted. It was such a great experience I kept adding things for them to do and all was taken care of. I got to see the layout of my panel beforehand via some fancy software. The actual work was done by many in the shop. John who runs the avionics side had Todd their master electrician do the install and most of the wiring. Many others in the shop worked on stuff as well and treated my old Mooney as if it were a late model Jet. I could not believe the respect they gave it. I also could not believe how Jake got the Garmin G5s flush mounted with such limited space. This is not easy to do in an M20C. A lot of custom fabrication took place. The experience of these people is truly noteworthy. All have been in the business for years and been there and done that. I spoke to some of the new hires and although new to the company many have served in the military working on airplanes or came from other reputable shops. The hangar is amazingly clean and well organized. Every part taken off your plane has a place and nothing is cramped on top of each other and mixed up with another planes parts like you see in other shops. I honestly do not know if I have ever seen a shop like this. I worked for many jet operators for almost all my career and none of the Gulfstream places I have seen are this nice. Your plane will be in good hands here and they work on Jets to Cessna 150’s all with the same level of professionalism. They also have an extensive parts department and a large space dedicated to avionics trouble shooting and repair. Your first contact will probably be with Sara who is the go to person in the office. She also does all the logbooks and book keeping. My log write-ups look better than any other shop this plane has been to. All the billing was correct and I feel like I am talking with family when I am in there. Curt the owner and Jake, John, Todd and the rest of the employees are some of the finest around. I was hesitant to have such a large project done without me being present but I can say that with constant updates and pictures always being sent to me that Daytona Aircraft Services should be on your very short list of places to consider. The final work order: Two Garmin G5s, GTN 650, GTR225, GTX345, FlightStream 510, JPI900, landing gear shocks and many other items. Oh and the post work experience has been just as pleasant. Stuff like how to customize the G5s and GTN for my liking and Todd even has been up with me to show me how it all works and to adjust some software settings etc. Not many mechanics will fly in planes they work on. Always seems to be an excuse with other companies. I can’t say enough good things about this place or my experience. Even if you do not have a Mooney, they work on all airplanes big and small, give them a try.4 points

-

I few Chad, the owner of Kubick Aviation, down to Kenosha, WI (KENW) to purchase a car for his son and then drive it back. Very nice morning to fly and caught some tail winds on the way down. After a several hour delay dealing with a check engine light on the purchase vehicle, I flew out after lunch to Antigo (KAIG) to pick up another Mooney pilot to pick up his recently repaired 252 at Chad's shop. He needed to get it off our airport before it's closed for a couple weeks for runway resurfacing. I ended up buying airline tickets out of Green Bay to New Orleans for a Dealer Meeting Monday through Wednesday for the same reason, couldn't fly back into my home airport on Wednesday. Man I hate flying spam can!! Here's a few photos of the flight. First one is of the one of the 4 local power dams dumping energy over the spillway. I bet the power company cringes when they have to do that. The next one is West Bend on my way back from ENW. Third picture is Lake Winnebago with the ice gone, while the Bay of Green Bay further north is still ice covered. Fourth one is Fondulac Airport and the last one is Oshkosh, quietly waiting for the big July event! Tom4 points

-

Frank, Paul said base price ASSUMES "mid-time" engine so essentially taking half the cost of an OH would take ALL engine value out. I agree that most buyers would prefer controlling the overhaul and having the engine warranty coming from THEIR purchase. It just makes things a bit cleaner. On the other hand, you end up with your new purchase out of service for some time during the inevitable overhaul. I'm in the same dilemma; but quite deeper into the situation. I have a 1600 TBO Rocket engine with 2075 hours on it (475 hours past TBO) and my new plane coming out of paint in two weeks. The Rocket has the cleanest oil filters I've ever seen, great oil samples, good compressions and very good oil consumption. I completed 3 trips to Florida this winter in it (1200 NM each way) with no issues (well, engine wise anyway. We won't talk about tires). If I were to keep it, I would clearly keep running it until something changed to make me concerned. If the reputation of the plane at my home drome is any indication of condition, I have two different guys that want me to keep it and let them buy a half partnership in it. Since my hangar partner/best friend/ Mooney A&P would help me replace the engine, my cost for the job would be less than someone paying a shop for everything. Still, crunching the numbers I just don't see either scenario being very good for me. To the O.P., I recommend NOT rebuilding. You've got enough desirable options on your plane I really don't think the engine time will stop it from selling, especially when the alternative is a lot higher selling price with a fresh OH. Tom4 points

-

After endless frustration, I finally got the plane degaussed adequately this weekend to compensate the SIRS compass to within 10 degrees on all headings. We used the degaussing coil ripped out of an old cathode ray tube TV and coiled it tighter to a diameter of about 7" before securing the loops together with zip ties. The coil was put in series with a light bulb socket with a 660W cone heater element in it (https://www.lightbulbdepot.com/products/details/di/660w-120-volt-cone-heater-heat-element-not-bulb/29036a/) to provide a ton of current. One must be very cautious not to burn oneself on the heater element and also to hold the coil outside the plane when turning off the power so as not to remagnetize stuff. We ran it over the front half of the steel cage , which helped but it was not enough. The engine mount was also heavily magnetized and we had to run the coil over that as well, and then it fully fixed the problem. BTW My CFII is a retired electrical engineer and did all the hard work. I certainly would have electrocuted myself on my own, but we have some Mooney degaussing expertise now. Three shops including an MSC declined to help along the way, but we got it done. If I had put that time into studying for the IR oral exam I'd be completely ready by now - I only need about 3 more hours.2 points

-

I placed a call to Mooney on Friday to get their insulation. Mechanic tried to say his was no biggie. Disagree. Thanks for the guidance here. Spent Saturday with mx lending a 3rd hand as the instruments were mounted for good. He made out like the fiber optic ring lights to illuminate the guages were a PITA. Looked fine to me. Finalized the middle stack - L3 9000, ifd440, sl30. Guy is bench wiring it all next week. Going to stay with steam for a few years to see how the pfd mfd market shakes out. Thanks to @Oldguy for his 12v elec vac backup. Also appreciate @Schinderhannes for the SL30 and 2nd indicator - pleasantly surprised ive got a standby indicator with GS. Oh, and giving a mouse a cookie is turning into a partial interior redo too. Floor and headliner. I need a bonus to pay for all this. Dang.2 points

-

2 points

-

I don't follow closely, but spot checking the classified's, it seems vintage planes are creeping up in price.2 points

-

Mr Kromer is speaking at the Mooney Summit this year about maximizing the performance of our Mooneys, and this would be a great topic to bring up during the Q&A. Although my guess is that he will say it would require another extended session to cover in detail. Forgive me for a word of caution out of concern for my Mooney brothers and sisters. Please don't take this discussion on Vne and its relation to flutter margins as anything other than educational, and stay within the published limits for your airplane. I believe I'm being the Master of the Obvious in stating this but you never know. The regulatory mathematics quoted by @jlunseth are the minimum requirements for aircraft certification and result in driving aircraft designs that can at a minimum meet those requirements as demonstrated during flight testing. The limit parameters of that testing get translated to KIAS for GA aircraft so that they are easily employed by the average pilot, although the numbers on your ASI may be different than the actual demonstrated aircraft limits to make the ASI numbers stay within the regulatory mathematics. But we have no way of knowing where the deltas are or how large/small they are, if indeed they exist, without seeing and understanding the flight test data. And it is not cost effective for a manufacturer to test beyond the required demonstration limits, not to mention the associated risk. Flutter is nothing to mess with unless you have the proper training and test support, and even then it can kill you very quickly. As @carusoam stated earlier, by the time most of us would recognize there was a problem the game would already be over. The "heart of the envelope" is a really good place to be, and staying within the published limits in a well-maintained aircraft will keep you safe. Cheers, Rick2 points

-

Instructors do not log PIC time based on being PIC. We log PIC based on part of 61.51 (the Universal Rule of Logging Flight Time) which says a CFI may log all training given time as PIC. Actually being PIC is irrelevant to the logging issue. in tems of acting as PIC, when I instruct in an owner's airplane, i make clear that the owner is PIC unless the owner is under a regulatory disability which precludes them from acting as PIC. And yes, our roles are clear.2 points

-

2 points

-

2 points

-

On April 26th my wife and I were traveling to Nassau for a long weekend in the Bahamas. We planned a stop in Daytona Beach for fuel. When we departed Huntsville, AL there was a low pressure to the west pushing a cold front to the east so we had to pass through about 90 miles of light to moderate rain. When we arrived at Daytona Beach the controler took us several miles off shore to enter a right base for 25R. To make sure we had our best glide in case of an engine problem I left the gear up until we started our descent on final. As we started to descend on final I put the gear switch down and started my gear checks. Switch down, manual gear indicator in the floor in the green and and gear down light on is my normal procedure. When I looked at the floor indicator I remarked to my wife that the light must have burned out as it was hard to see the green indicator but it was there and I could see it. When I looked at the annunicator gear light it was off. At this point I knew something was wrong but I didn't know what. I am still at a couple thousand feet so I had time to cycle the gear up and back down and had the same indications. I checked the manual gear cover to be sure it was latched and I pulled the manual gear handle to confirm the gear was down. It is now time for a different plan as I knew I wasn't landing without a gear light since I didn't trust that the gear was locked down even though I was confident the gear was down. I thought I probably had a stuck or broken gear down switch. I have always felt and I teach my complex students that the worse place to diagnose a problem is in the pattern. Close to the ground is no place to deal with the distractions of a gear problem. My call to tower was "Daytona tower, Mooney 49Q has a gear problem and needs to depart the pattern to troubleshoot the issue". He immediately offered an orbit over the speedway and a climb to 1500 feet which I took. In hindsight, maybe not the best spot since I had to stay away from the runways which was a lot more complicated because the autopilot was randomly disconnecting. Lots of distractions during the entire event including the tower asking fuel and souls on board. The tower was great during the entire event but I did have to ask him to standby once since I was feeling overloaded. Flying, troubleshooting and talking was one too many things to do. Things got really quiet after that. After arriving at the speedway and getting the altitude back where it belonged I started troubleshooting the gear issue. At this point I planned to manually put the gear down since I had tried all the electric troubleshooting I could. When I reached to the circuit breaker panel to pull the electric gear breaker I noticed the gear indicator breaker was popped which explained the lack of lights. I pressed the gear indicator breaker back in and put the gear down which promptly tripped the breaker again. Not good. Next plan is to pull the breaker and manually extend the gear. That worked but I still didn't have a gear light. I reset the gear light breaker and the lights came on. I told the tower that I had a gear down indication and I was ready to land. He sent me on a fairly long downwind since he had two jets to land. I didn't realize until later but the controllers were holding the other planes on the ground to give us the runway. During the downwind leg I heard someone asking about the alert aircraft and realized they were talking about us. That was a bit sobering. When we turned final we had two fire trucks and an ambulance on our left. They had four trucks at various places on the right of the runway. Lots of airplanes holding on the parallel taxiway since Emery Riddle does a lot of training here. Ok, this is for real. I made a nice slow descent and as gentle touchdown as I could. The gear stayed locked down and after I made the right turnoff on the taxiway I felt fairly confident that the gear wasn't going to collopse. We had one of the alert trucks and a fire truck follow us for a while. The alert truck followed us to the ramp and the airport authority guy took our statement. End of the incident but I still have a broken airplane and reservations in Nassau. First step is to call Joey Cole and get some advice. He is at lunch and will have to call me back. Daytona Aircraft Services is on the field and were kind enough to put the plane on jacks to check the gear. We performed several gear cycles and no issues were seen. We pulled the gear indicator and confirmed that the gear would lock down even if the gear down indicators wouldn't light. The guys at Daytona Aircraft Services were confident that there were no issues with the gear and that I just had a problem with the gear indicator system. When I spoke with Joey and told him the problem his first question was did I fly through a lot of rain. I said that I had flown through about 45 minutes of moderate rain that morning. Joey said that water can cause issues with the gear indicators and that was probably what happened. At this point I felt comfortable that the gear would come down even if the indicators failed to work. We fueled and loaded up to depart for Nassau. When we arrived in Nassau the gear extended and the lights lit with no issues. When we get home I plan to pull the wiring diagram and check for anything that could cause the breaker to trip. What I did right: 1) Left the pattern to diagnose the problem 2) Managed the flight and got all the help I needed 3) Didn't do anything to make it worse. I was really tempted to cycle the gear instead of getting it on jacks. How much worse would it have been if I had the gear down, put it up and then it wouldn't come down. 4) Landed at a field that had a Mooney service center on the field. What I did wrong: 1) I should have gotten out the checklist instead of doing everything by memory. I would have caught the popped breaker sooner. 2) I should have cancelled my IFR clearance sooner. I didn't need it and it made the controller's and my job harder. I definitely busted my assigned altitude due to distraction. I didn't declare an emergency but I am sure the tower controller did it for me. It will be interesting to see if I hear anything from the FAA about the event.1 point

-

Update on this thread: Unfortunately, this newbie was editing a response to a user's post on this thread, and he accidentally deleted everything : ( I want to thank everyone for their input and thoughtful ideas. I received a great deal of very valuable information. Please feel free to continue posting in this new thread if you see anything you'd like to mention regarding the new Mooney.com. Lance1 point

-

I've found that whether it costs anything extra or not varies (along with policy terms, underwriting, etc) from company to company, aircraft to aircraft, owner to owner, and CFI to CFI. And there is a very strong line of thought that having an additional named insured always cost something, even if it is just dilution of policy limits. In the accident situation in which you and the owner are both defendants, you might not have the same insurance provided lawyer. There is a potential conflict of interest and an insurer might decide to hire separate attorneys. Particularly if the owner policy is one in which defense costs are part of and not in additional to liability limits, it's another possible dilution of the policy limits and yet another reason for a CFI to have his or her own liability policy, even if it's just to cover costs of defense.1 point

-

Well here is your chance to become one. Mooney is looking for a test pilot (tempting but that is a young mans game) https://recruiting.myapps.paychex.com/appone/MainInfoReq.asp?R_ID=1893063&B_ID=91&fid=1&Adid=0&ssbgcolor=17143A&SearchScreenID=7751&CountryID=3&LanguageID=21 point

-

Really? Wow, thanks. That I’m sure will change shortly!1 point

-

I bought my M20-C five weeks after my PPL. I'd suggest renting a retract and getting the complex signoff while you are shopping, it will make it easier to find insurance, as well as cheaper. No need to do the Cherokee thing first if you know you want a Mooney.1 point

-

Wow!! congratulations. I think at this moment in time you likely now have the most advanced and modern avionics in a Mooney on the planet. Bar none.1 point

-

1 point

-

2 of the 3 left are here on MS, although not too terribly active. @Sven has a very nice 1963 model, N6630U This one is also a 1963, N6651U, but in not as great condition The last, and rarest is @ronmacewen's 1964 model, N1916Y, which is the only one with a fixed pitch prop and excellent panel. They were asking not much more than this, for a much much MUCH nicer panel. Coincidentally, I just happened to randomly sit down next to a him at a pancake breakfast in Arcadia, FL a year or two ago and we got talking about airplanes. I mentioned I had a Mooney, as did they. They mentioned they were selling theirs, and it was rare fixed gear model. Process of elimination was easy: "Oh! You have N1916Y!". They were impressed I was familiar with their plane. I went out and showed them my converted model. Great people.1 point

-

One interesting anomaly about the PIC is if the safety pilot CFI or not has a basic med as opposed to a 3rd or higher class medical. Basic Med only covers the PIC so when acting as a safety pilot with a PiC the left seater if PIC and under a hood means the safety pilot with BasicMed is not legal to act as a safety pilot. This is a result of the way the law was written. The workaround is to declare the safety pilot PIC when the owner/operator is under the hood. This can change at any point during a flight but should be briefed if one is flying with someone operating with BasicMed.1 point

-

F & J, yes; E, I dunno; Cs are 30, 30, 30--you have that heavy fuel injection system!1 point

-

Way to go, Lance! You really didn’t have to go that far to demonstrate your awesome human skills... A few things I was looking for in the site improvement list... 1) A Mobile I-device friendly version of the site. 2) reName the shop button to the ‘pilot shop’ button... I want to send some traffic towards the shirts and paraphernalia area... 3) Update The list of MSCs with modern detail including their websites and emails. 4) We want to be able to find them when he have issues while out on the Victor Highway. 5) Going forwards, Gumps, Gumps, Gumps... you are now free to move about the country.... We might be able to see if there is a back-up copy of this thread, if interested. Note: @mooniac58 Best regards, -a-1 point

-

1 point

-

1 point

-

Thanks everyone for your help. The smell is gone. I’ve flown another 15 hours aroma free. This is a great resource!1 point

-

Let me rephrase. I've connected both TIT gauges to one TIT probe (like JPI said was possible) to see just how far off the two readings are. Until I've verified which reading is closes to accurate, I'll use the higher (830) as the limiting reading. I can not fly with the OEM disconnected to see what the EDM would read solo, and I'm in no hurry to drill a second hole in the exhaust when the EDM can be calibrated. Again, both readings were very close in the 1300*F range. In the 1400's the differences were around 50*F and continued to increase through the 1500's. The OEM indicator topped out around 1530*F with the EDM at 1630*F. I'll do some more testing.1 point

-

1 point

-

Glad the gear is fully up and stowed now! Looks great. The Mooney logo in the upper left doesn't show correctly in Firefox. I just pulled up Internet Explorer and it displays correctly there. Cheers, Dan1 point

-

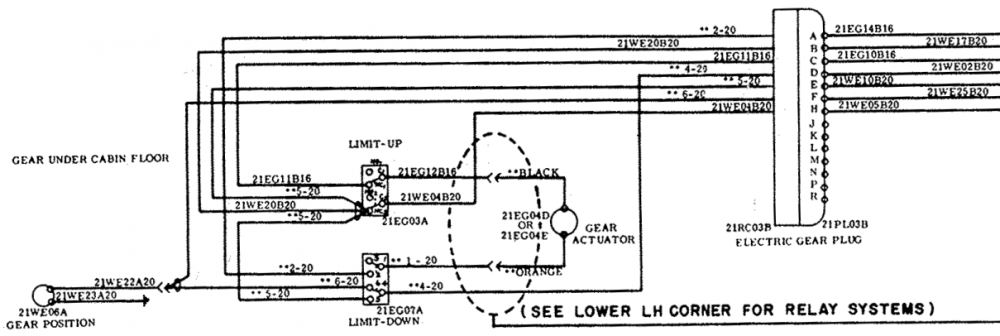

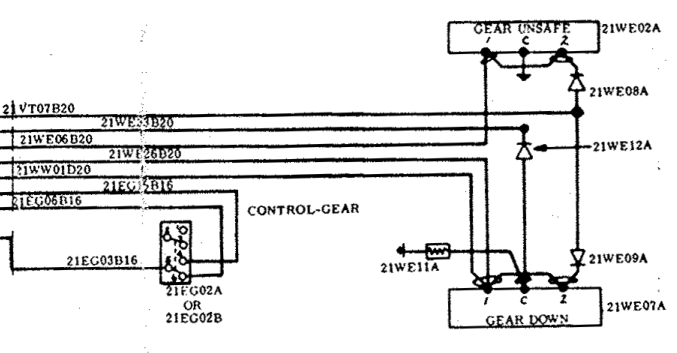

I don't have the schematics for an M20J handy, but I have late-model M20F schematics which I'm betting are similar. Here's the portion of the schematic showing the gear motor, the limit switches in the belly, and the light that controls the floor indicator lamp. Note that one side of the limit-down DPDT switch controls the relays that shut off the gear motor, the other side goes to the floor lamp. The schematic happens to show the switches in the gear-down position, i.e. power applied to the lamp and power removed from the gear motor. That ring terminal splicing off the floor lamp indicator goes to the annunciator light on the instrument panel. In other words, the same connection powers both the "Gear Position" floor lamp and the "Gear Down" instrument panel light. If you trace that wire in the schematic, it leads to the panel annunciator lights themselves: Notice the annunciator lights have one common (ground) terminal, but two terminals for power (applying voltage to either one will light the lamp). The "2" terminals on the right side connect to the push-to-test switch. The "1" terminals on the left side connect to the limit switches in the belly... and also the floor lamp indicator in the case of the gear down indicator, as explained above. In particular, when the down-limit switch moves to the "Gear Down" position, power is applied to the "1" terminal of the Gear Down indicator above. So, couple of things to understand about failure modes. First, if the gear indicator breaker trips, it affects both the panel annunciator and the floor lamp. These two gear down lights are not on independent circuits, they're only "redundant" in the case of a burned out bulb. The good news is, the mechanical lubber line on the floor indicator is still a good indication of gear down regardless of any lights. Second, the terminals on the instrument panel indicators have to be physically close together since there are three of them - maybe 1/4" to 1/8" apart. If you get a drop of moisture on the back of the indicator - perhaps streaming in through imperfectly sealed access panels just outside the windshield when flying in rain - it can form a short between the terminals. If moisture forms a short between terminal "1" and terminal "C" of the gear down indicator, this can create an electrical short between power and ground - but not until the gear reaches the down position and the limit switch in the belly closes to apply power to terminal "1". If you put the gear back up, power is not applied to terminal "1" and the breaker can be reset. If you put the gear back down, the breaker will pop again when the down limit switch in the belly closes. Sounds like this may be what happened to you. Hope that helps.1 point

-

I’d recommend mounting the guns in the wings, just outboard of the fuel tanks. Any closer and you’d have to start thinking about a synchronism mechanism. Load the belts through the inspection doors. Convergence should be set to about 350 yards. Then an it’s just a mafter of finding a bonanza or Cessna to roll in on. oh...... you meant in the cabin....1 point

-

1 point

-

In your case isnt it, "once you go turbine"?1 point

-

I'm in agreement with what others are saying. What would you ask for the plane if it had a fresh engine? I've never been in the market for an Ovation and so don't know how to price it myself. But I think if you worked out a fair price for an Ovation with a fresh engine and then subtracted the cost of the overhaul from that number and listed it, it would sell quickly. I'd much rather buy your plane with a timed out engine at the right price and then get it done myself.1 point

-

As an experienced owner I'd rather buy yours as-is and keep flying. A newbie probably would rather have a fresh engine. I suspect it will sell faster with a quality overhaul, but you'll end up with less net money in your pocket. I'd just list it with a realistic price to account for 90% of TBO and see what happens... You can always overhaul later. Sent from my LG-US996 using Tapatalk1 point

-

Back in 2011 Avemco asked for 5 hours in type and 50 retractable. When I came back to them with M20E, they upped time in type on me and charged $1800, with promises to relieve the premiums after I get 25/125. It's all over the place. As for getting comfortable, it took me some 3 hours or so, although that was mostly landings. If you just cruise for hours, it's not teaching you anything that's not in the manual. Everyone I asked similarly found insurance requirements excessive. They should ask for some 5..8 high task load landings with CFI instead, IMHO. You know, when ATC asks to maintain forward speed to final or you're #4 for landing at a fly-in. That's when people forget to put gear down. The rest is really easy on a Mooney, it flies great at 100 mph.1 point

-

1 point

-

Aircraft Spruce. A good website to have bookmarked for quick reference. https://www.aircraftspruce.com/catalog/elpages/whelenstrobesystema650.php?recfer=79541 point

-

1 point

-

1 point

-

Another Young Eagles rally under the belt for N6744U at the 3rd Annual Wings Over Suwannee festival. This plane has flown over 1,200 kids since Young Eagle's inception in 1992 and I've done about 200 of them myself in the past 2 years.1 point

-

Took a friend flying yesterday along with his daughter. She had never flown in a plane of any kind before. After some coastal flightseeing we had lunch in French Valley. After we had lunch I put her in the right seat and she got some time flying us around. If anyone is looking for a great time, find someone who hasn't flown GA before, or if you are lucky someone who has never flown before and take them up! Her First Flight1 point

-

Quick trip today supporting the not-so-quick process of obtaining a PIN to fly into the Maryland 3 airports. First filled out the application along with scans of documentation. Today fingerprint collection by a TSA-vetted technician—I elected to use one at Harrisburg PA. Next up, an in-person verification that I resemble my picture IDs. Nice spring day flight in the Mid-Atlantic area.1 point

-

Sorry I cannot answer your question, but looks like a good reason to upgrade to the JPI EDM 9001 point

-

I went under the hood today for about an hour. The results weren't nearly as bad as I anticipated, but this took place during the break-in period so flying a GPS approach at WOT was challenging.1 point

-

$120 for a god-damned dipole whip? You can literally make one out of a coat hanger that has identical electrical properties. Where do these people get off?? Sent from my Pixel using Tapatalk1 point

-

Put them on, get IA to sign logbook entry and forget about it. Keep your old bulbs just in case. It’s what I did. I won a set of NavStrobe Sextant as a door price at the Mooney Summit. Just a bulb replacement like the Whelen but they strobe too (wing tip and tail light) simply by turning them on/off twice within 5 seconds. Much brighter than what I had, the strobe function makes it even more visible, and I’m not losing any sleep over it. Sent from my iPad using Tapatalk1 point

-

The references I was referring to are AC43-210A and Order 8110.37. I plan to use these reference in the minor alteration log entry. My comments were only to see if anyone else had better data. Keep in mind this is not just for my personal Mooney... -Matt1 point

-

I want to update this thread on my problem resolution. So I received the Whelen HDACF supply back from Whelen who thoroughly inspected it and found it to be working just fine. Upon bolting it back to the belly, I noticed the aluminum spacers were quite sticky - more than old oil, varnish, etc. I think the original installer used some sort of adhesive to hold the half-inch aluminum tubing spacers to the belly so they wouldn't naturally fall off when trying to install the strobe pack. It is my belief that this "stick" crap is shielding the strobe pack from a solid connection to ground. If you reference my photo above, you can partially see the ground eyelet crimp that is fastened with one of the AN bolts. I inspected the bolts to be sticky as well. I went into the cockpit and saw that there are some thin aluminum reinforcement plates on the top surface of the belly. The bottom of them was sticky. All the sticky crap was cleaned off. I sprayed all of the ground contact areas down with aerosol Deoxit D5 contact cleaner. I then applied a thin light coating of Deoxit D100 "Power Booster" lubricant/enhancer to the contact surfaces. Guys this Deoxit stuff is amazing. They advertise how it "improves conductivity" etc. and I've witnessed this work for other applications using an ohmmeter. I recommend cleaning up your antenna connectors and such with this stuff too. Regardless, I painstakingly installed the spacers (a real P.I.T.A.) and tightened everything up. I then cleaned all of the connectors with the D5 spray and then coated them with the D100. All I can say now is that everything is working GREAT now. I even plugged the strobes back in to Alternate instead of flashing together - it is almost double the brightness per Whelen's spec sheet (42 vs 21 joules). I'm surprised the last owner didn't do it that way. So Deltchief - check your connections! I'm surprised that it appears to have been something so trivial in my bird. Well I'm hoping that was the problem...1 point

.thumb.jpg.fae0be1e8fd71696a22ca12ed3faf498.jpg)